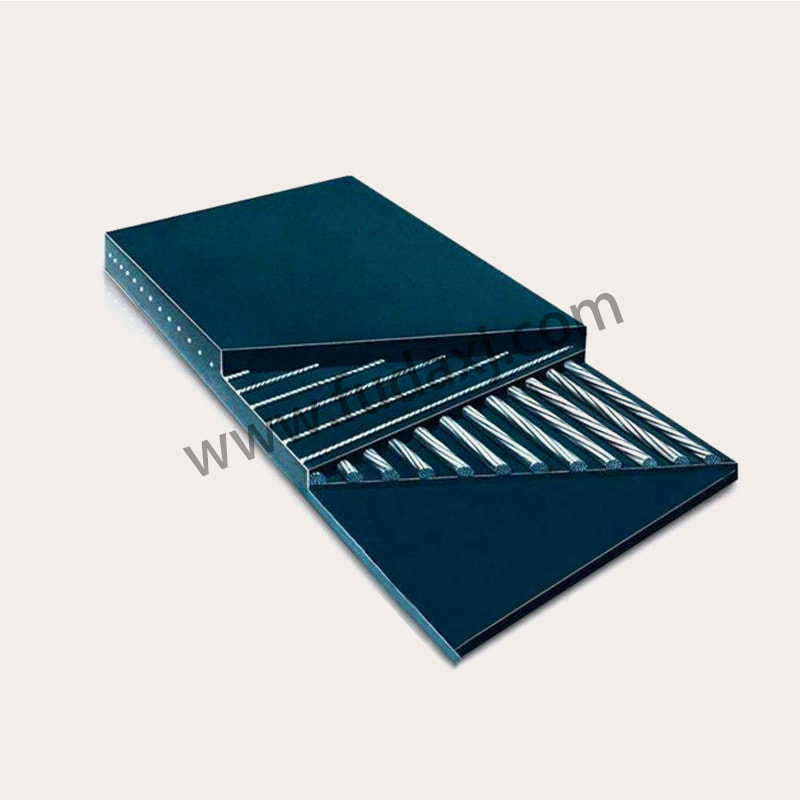

Steel rope conveyor belt

The steel wire conveyor belt is composed of core rubber, steel wire rope, cover layer and side rubber. It has the advantages of mildew resistance, moth resistance, aging resistance, good heat resistance, high tear resistance, and the belt surface can be renovated after being worn.

Characteristic: high tensile strength. It has good impact resistance, long service life, small use elongation, good channeling performance, good bending resistance and flexibility, and is suitable for long interval, long haul and high speed material transportation.

How to select conveyor belt

The selection of conveyor belt of belt conveyor is based on the factors such as conveyor length, conveying capacity, belt tension, conveyed material characteristics, material receiving conditions and working environment.

The selection of conveyor belt shall meet the following requirements:

Polyester fabric core conveyor belt should be selected for short distance belt conveyor. For belt conveyors with large conveying capacity, long haul distance, large lifting height and large tension, steel cord conveyor belt should be selected.

The conveyed materials contain blocky materials with large size, and when the direct drop of the receiving point is large, the impact resistant and tear resistant conveyor should be selected.

The maximum number of cloth layers of the layered fabric core conveyor belt should not exceed 6: when the conveyed materials have special requirements on the thickness of the conveyor belt, it can be appropriately increased.

The underground belt conveyor must be flame retardant.

English

English 简体中文

简体中文 Español

Español عرب

عرب

English

English

Fax: 0086-576-83019528

Fax: 0086-576-83019528